Portable, adjustable, and vesatile lamp

Bachelor’s degree project in collaboration with Belid Lighting Group - 2025

Bachelor’s degree project in collaboration with Belid Lighting Group - 2025

Global warming and ongoing conflicts are increasing the risk of disrupted infrastructure, leading to more frequent and prolonged power outages.

Developed in collaboration with Belid Lighting Group, this project explores how a lamp can bring comfort and reassurance during darkness. Designed as a natural part of the home, always present, not just brought out in times of crisis.

Developed in collaboration with Belid Lighting Group, this project explores how a lamp can bring comfort and reassurance during darkness. Designed as a natural part of the home, always present, not just brought out in times of crisis.

Rooted in traditional manufacturing, the design embraces a timeless simplicity meant to age gracefully. Its spun recycled aluminum body gives the lamp a tactile lightness and strength, allowing it to be moved effortlessly while standing resilient against wear and corrosion.

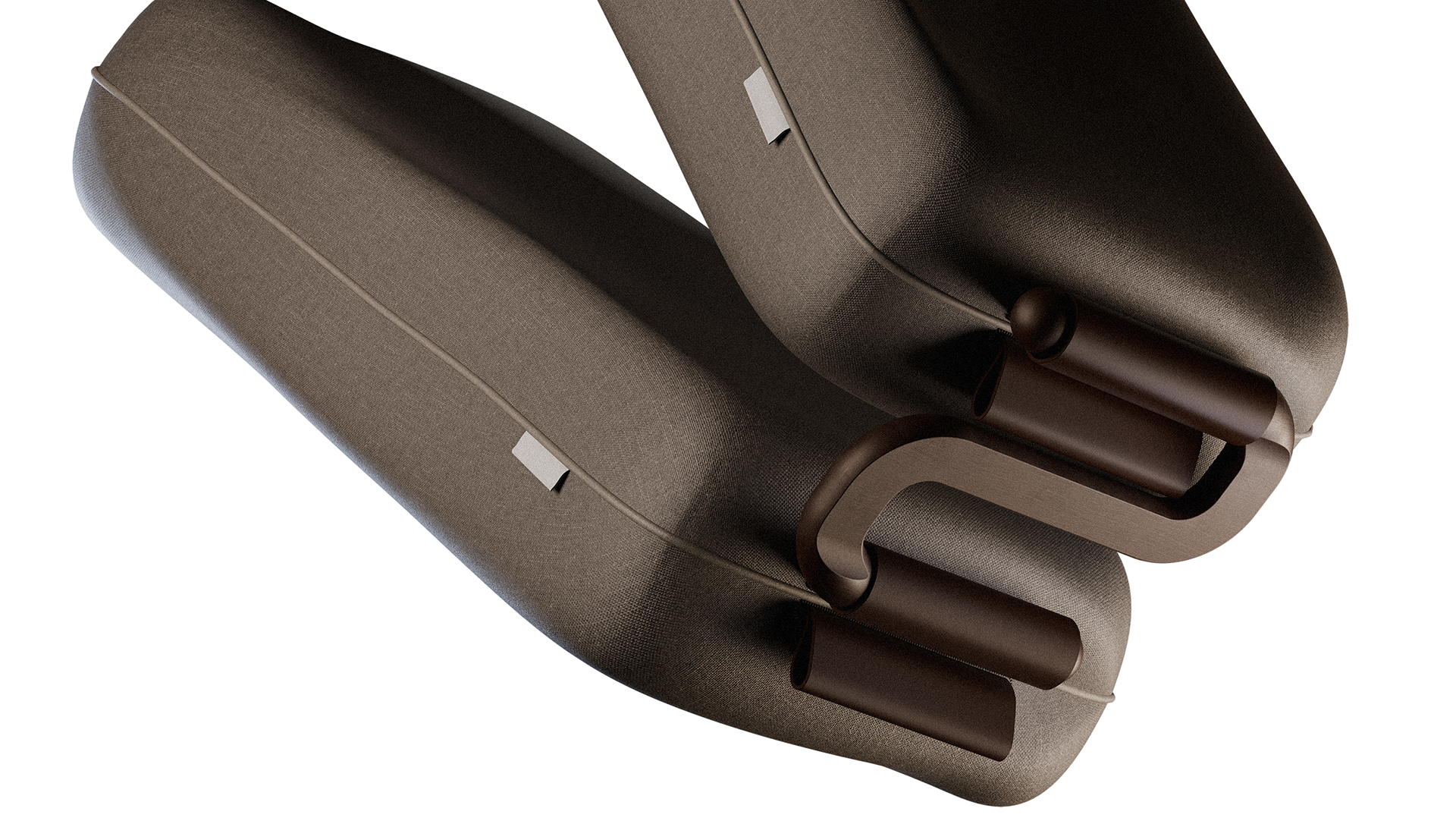

Lampshade with magnetic mount, allowing the light to be tilted and directed, and easily removed or replaced for transport.

Dymo crank for backup charging

On off switch with step dimmable touch control

After initial sketching phase, the development continued through both physical and digital explorations in three dimensions.

Scaled 3D prints at a 1:5 ratio were created to study form, proportion, and balance, while lamella models helped evaluate real-life scale and spatial presence.

The final concept was refined in CAD and verified through full-scale 3D printing to ensure accuracy and integrity in every detail.

Scaled 3D prints at a 1:5 ratio were created to study form, proportion, and balance, while lamella models helped evaluate real-life scale and spatial presence.

The final concept was refined in CAD and verified through full-scale 3D printing to ensure accuracy and integrity in every detail.

The research for this project focused on understanding the company and the needs of users in both private and commercial markets.

Interviews, testing, light experiments, and factory visits were conducted to ensure that the design of the lamp meets the expectations of both the company and its users.

Interviews, testing, light experiments, and factory visits were conducted to ensure that the design of the lamp meets the expectations of both the company and its users.

Scaled 3D printed models (1:5) used to evaluate form and proportions.

Lamella models built to evaluate real-life size and spatial presence.